About us

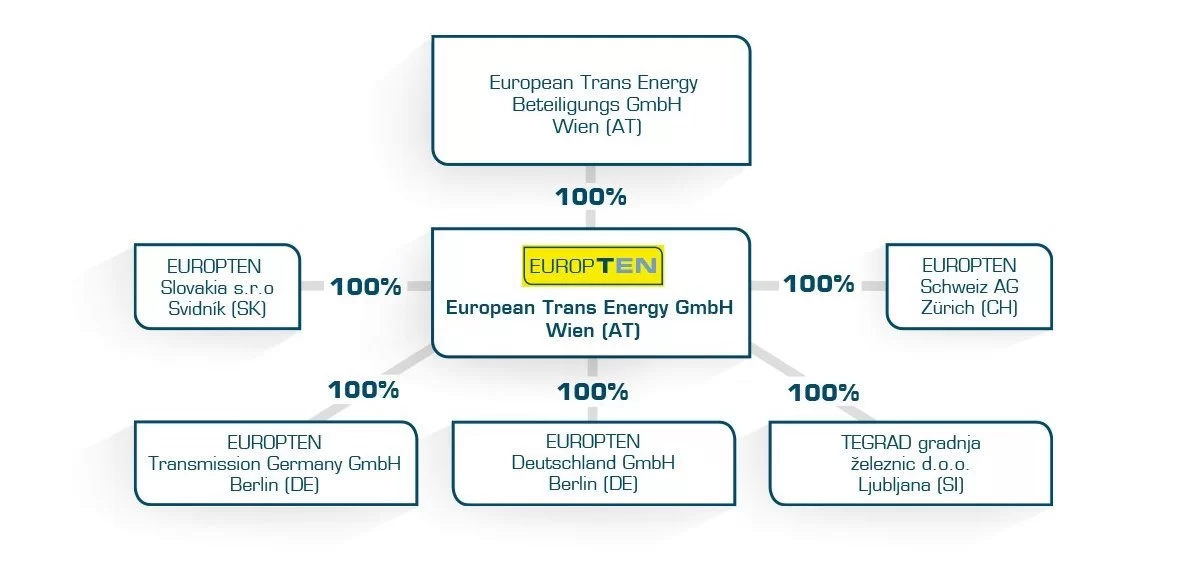

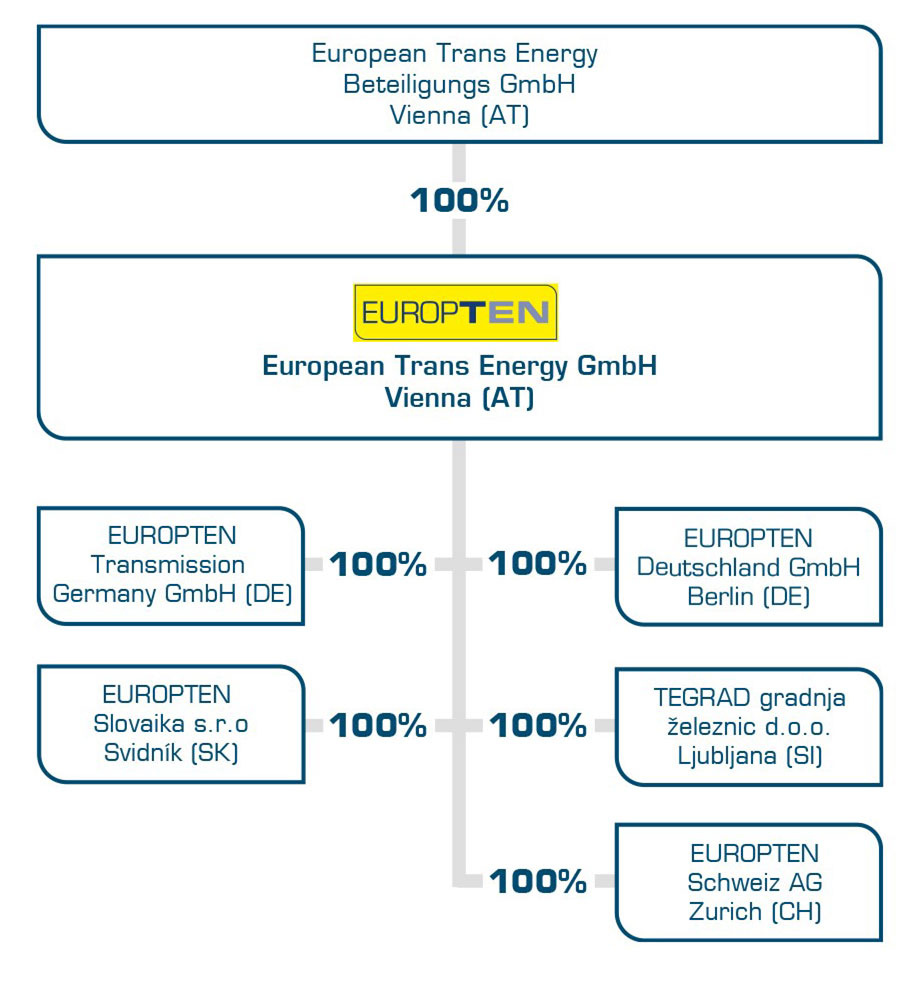

The EUROPTEN Group consists of six operating companies and has been growing for over 100 years.

EUROPTEN handles catenary projects in Austria, Germany, Slovenia and Switzerland, and overhead line construction projects in Austria, Germany and Slovakia.

In total, with 700 employees and currently around 45 projects, we are developing an annual operating performance of €180 to €200 million.

Management

As a specialist in line construction, EUROPTEN has been one of the leading providersof energy infrastructure systems in Austria, Germany, Switzerland, and Slovenia for more than 100 years.

The EUROPTEN Group management team consists of the management of the operating parent company European Trans Energy GmbH and the heads of the individual business divisions. Transparent management, an open-door policy and handshake quality are a matter of course for us.

Professional expertise and responsible employee management, as well as integrity and commitment, are essential success factors in our corporate governance.

Economic responsibility and understanding the needs of employees on a day-to-day basis ensure the growth and progress of our company.

Training & Further Education

EUROPTEN recognises your potential and promotes your development.

Particularly in an environment of ongoing change and technical innovation, staff training and development are crucial. For this reason, we continuously provide training and further education in business and technological topics in close consultation with our employees.

Our History

2015

Shares in EUROPTEN previously held by PORR were taken over by the Androsch Privatstiftung and Dörflinger Privatstiftung. Each of them holds 50% of the shares in European Trans Energy Beteiligungs GmbH.

Company foundation EUROPTEN Transmission Germany GmbH, based in Berlin.

Company foundation EUROPTEN Schweiz AG, based in Dübendorf.

Acquisition of 65% stake in RISMANN s.r.o., based in Svidník, Slovakia, and expansion of the overhead line business.

1920

The Viennese Gesellschaft für elektrische Industrie was commissioned to build the railway line between Linz and Hiesendorf which was part of the first 110 kV line in Austria between Linz and Steyr. The HW (high-voltage lines for wide span systems) division was founded to carry out this first large-scale line construction order. This division was the origin of ELIN Leitungsbau.